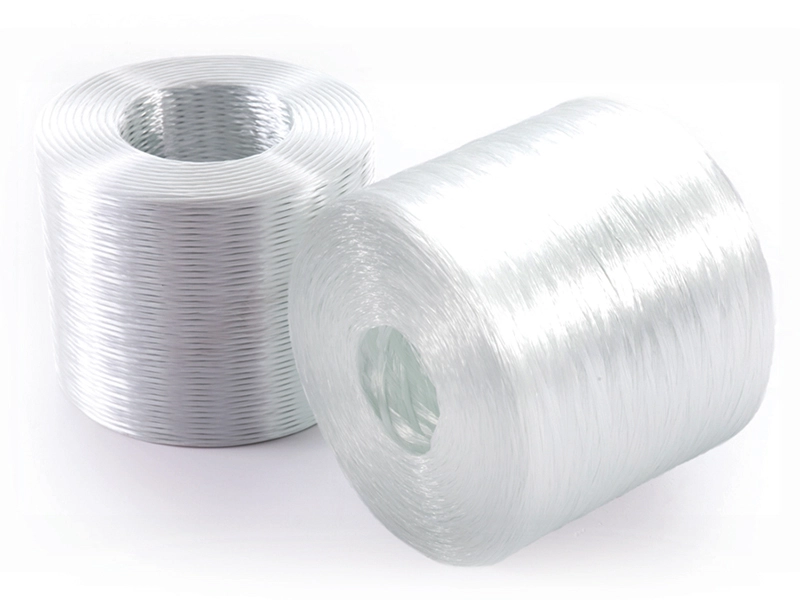

Chopped Strand

Chopped strand fiberglass, also known as chopped strand mat (CSM), is a type of fiberglass reinforcement used in composite materials. It is a popular choice for various applications due to its ease of use, cost-effectiveness, and good mechanical properties.

What is chopped strand fiberglass?

Chopped strand fiberglass is a type of fiberglass reinforcement made from short, chopped strands of glass fibers. The fibers are typically 1-4 inches (2.5-10 cm) in length and have a diameter of around 0.010-0.020 inches (0.25-0.50 mm). The chopped strands are randomly oriented and held together with a binder, usually a polyester or epoxy resin.

Properties and characteristics:

Chopped strand fiberglass has several advantages that make it a popular choice for various applications:

- Easy to use: Chopped strand fiberglass is easy to handle and can be easily molded into complex shapes.

- Cost-effective: Compared to other types of fiberglass reinforcements, chopped strand fiberglass is relatively inexpensive.

- Good mechanical properties: Chopped strand fiberglass has good tensile strength, flexural strength, and impact resistance.

- Chemical resistance: It is resistant to many chemicals, including water, acids, and bases.

- Thermal insulation: Chopped strand fiberglass has good thermal insulation properties, making it suitable for applications where heat resistance is required.

Applications:

Chopped strand fiberglass is widely used in various industries, including:

- Automotive: Chopped strand fiberglass is used in car bodies, bumpers, and other components.

- Marine: It is used in boat hulls, decks, and other marine applications.

- Aerospace: Chopped strand fiberglass is used in aircraft components, such as wings, fuselages, and control surfaces.

- Construction: It is used in building insulation, roofing, and wall panels.

- Sports equipment: Chopped strand fiberglass is used in surfboards, kayaks, and other sports equipment.

Manufacturing process:

The manufacturing process of chopped strand fiberglass involves several steps:

- Glass fiber production: Glass fibers are produced through a process called drawing, where molten glass is drawn through a spinneret to create fibers.

- Chopping: The glass fibers are then chopped into short strands.

- Binding: The chopped strands are held together with a binder, such as a polyester or epoxy resin.

- Forming: The chopped strand fiberglass is then formed into the desired shape using a mold or die.

- Curing: The chopped strand fiberglass is cured in an oven or under pressure to create a solid, rigid part.

Overall, chopped strand fiberglass is a versatile and widely used material in various industries, offering a good balance of properties, ease of use, and cost-effectiveness.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com