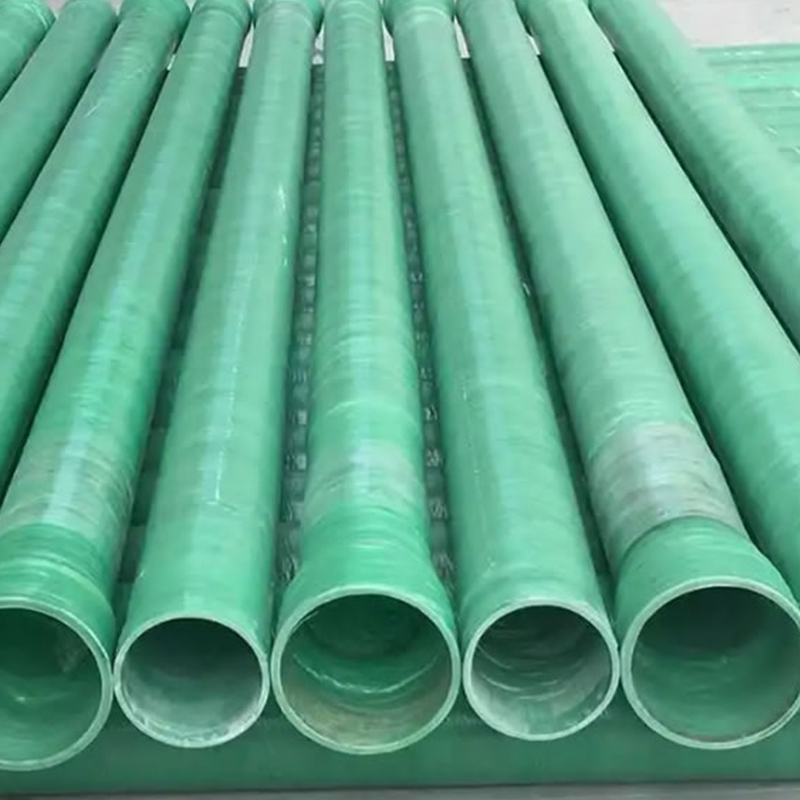

JUSHI Fiberglass Products For Pipes

Filament Winding Process

Traditional Filament Winding

In the filament winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

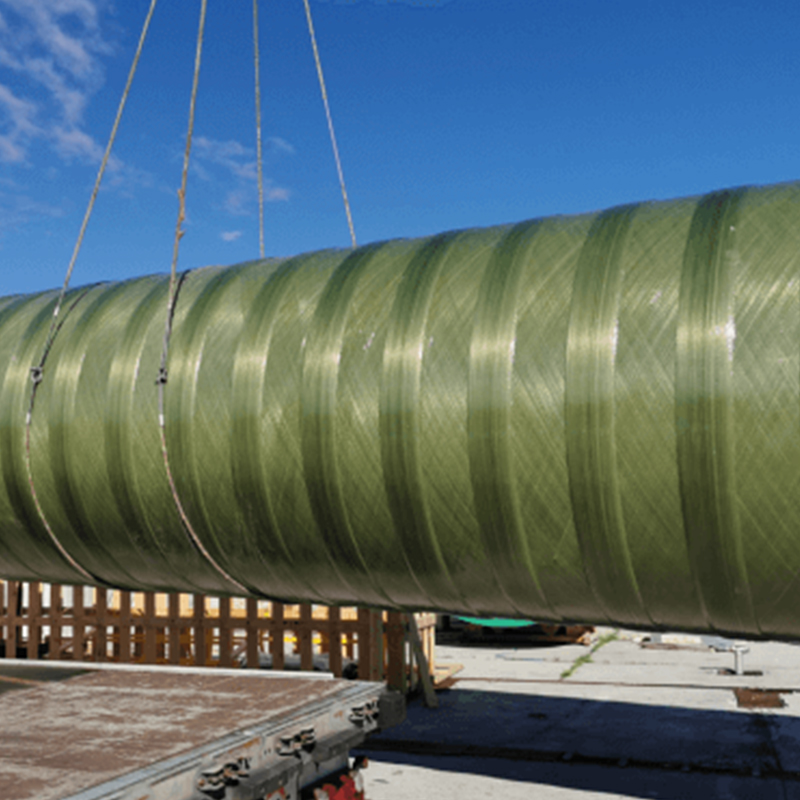

Continuous Filament Winding

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

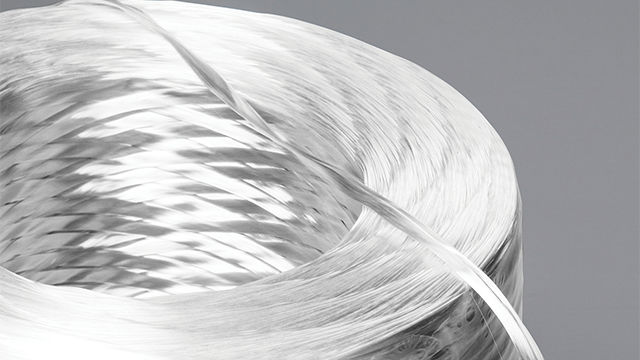

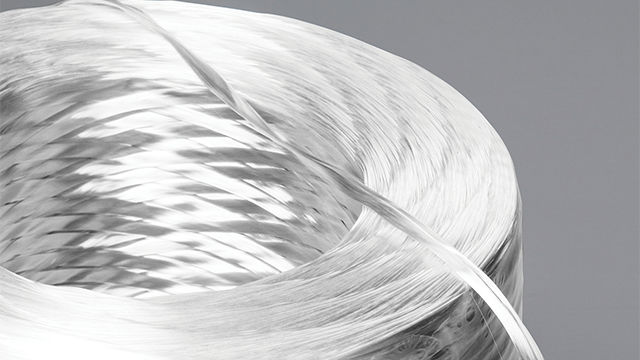

Assembled Roving for Filament Winding

Assembled Roving for Filament Winding is specially designed for FRP filament winding process and compatible with UP, EP and VE resins. Its final composite product delivers excellent mechanical properties.

| Product Code | Product Features | Typical Application |

|---|---|---|

| 266 | Fast wet-out, low fuzz and high strength | Pipes and storage tanks |

Assembled Rovings for Chopping

Assembled Rovings for Chopping are coated with a special silane-based sizing and compatible with UP and VE resins. They are designed for pipe production, offering excellent water resistance and chemical corrosion resistance.

Direct Rovings for Filament Winding

Direct Rovings for Filament Winding are compatible with UP, VE, EP, PU and PF resins. Their main applications include FRP pipes of various diameters for conveying water and corrosive chemicals, high-pressure oil pipes, pressure vessels, storage tanks, and insulation materials such as utility poles and hollow composite insulators.

Powder Chopped Strand Mat

Powder Chopped Strand Mat is made of randomly distributed chopped strands held together by a powder binder. It is compatible with UP, VE, and EP resins. The roll width ranges from 200 mm to 3,120 mm.

Centrifugal Casting Process

The raw materials, including resin, chopped reinforcement (fiberglass), and filler, are fed into the interior of a rotating mould according to a specific proportion. Due to centrifugal force the materials are pressed against the wall of the mould under pressure, and the compound materials are compacted and deaired. After curing the composite part is removed from the mould.

Assembled Roving for Centrifugal Casting

Assembled Roving for Centrifugal Casting is coated with a silane-based sizing, compatible with UP resin and delivers excellent choppability and dispersion, low static, fast wet-out and good mechanical properties of composite products.

| Product Code | Product Features |

|---|---|

| 622 | Fast wet-out, extremely low resin absorbabiliy, high strength of composite products, designed for the European market |

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com