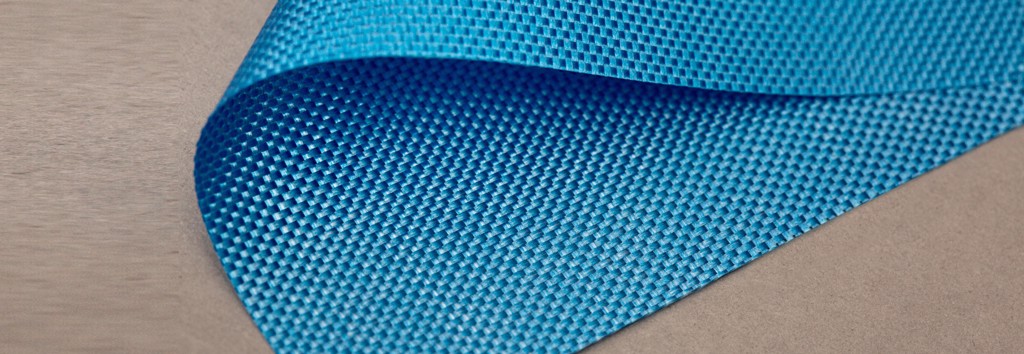

The yarns are arranged at specific angles (e.g. 0, 90, ±45°) in multiple layers, typically 2-6 layers. Short-cut and non-woven layers can also be included, followed by sewing the layers together with polyester yarns in a warp knitting pattern to create a multiaxial fabric, also known as multiaxial warp knitted fabric. These fabrics are rigid and effectively utilize the mechanical properties of glass fibers. Specifically, we emphasize the weight in one direction (e.g. 0 degrees) of the multiaxial fabric, referred to as unidirectional fabric. Multiaxial fabrics find applications in vacuum infusion, prepreg, winding processes, primarily in manufacturing wind turbine blades, pipes, etc. Epoxy resin (EP), polyester resin (UP), vinyl resin (VE), polyurethane resin (PU), and polyurethane resin (PU) are commonly used resins for these fabrics.