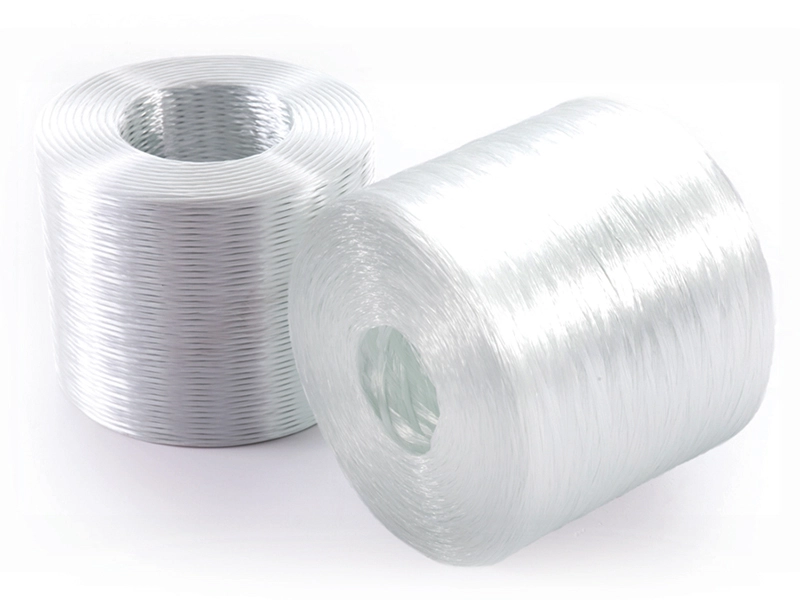

Assembled Roving

Assembled roving, also known as assembled roving fabric, is a type of textile material used in various industrial applications. It is created by assembling multiple layers of roving, a bundle of parallel fibers, to form a thick, dense, and strong fabric. In this overview, we’ll delve into the details of assembled roving, its properties, advantages, and common uses.

Properties of Assembled Roving:

- High Strength-to-Weight Ratio: Assembled roving fabric exhibits exceptional strength, stiffness, and toughness while maintaining a relatively low weight.

- Improved Impact Resistance: The layered structure of assembled roving provides enhanced impact resistance, making it suitable for applications where high energy absorption is required.

- Chemical Resistance: Assembled roving can be designed to resist various chemicals, including acids, bases, and solvents, depending on the type of fibers used.

- Thermal Insulation: The fabric’s dense structure provides excellent thermal insulation, making it suitable for applications where temperature control is crucial.

Advantages of Assembled Roving:

- Customizable: Assembled roving can be tailored to meet specific requirements by adjusting the type, number, and orientation of fibers.

- Cost-Effective: Compared to other composite materials, assembled roving can be a more cost-effective solution for certain applications.

- Easy to Process: Assembled roving can be easily cut, shaped, and molded to fit complex geometries.

Common Uses of Assembled Roving:

- Aerospace Industry: Assembled roving is used in aircraft and spacecraft components, such as fuselage, wings, and rocket components, due to its high strength-to-weight ratio and resistance to extreme temperatures.

- Automotive Industry: The fabric is used in car parts, such as chassis, body panels, and engine components, to reduce weight and improve fuel efficiency.

- Marine Industry: Assembled roving is used in boat hulls, decks, and other structural components due to its high strength, stiffness, and resistance to water and corrosion.

- Sports Equipment: The fabric is used in high-performance sports equipment, such as bicycle frames, golf clubs, and tennis rackets, to achieve optimal strength, stiffness, and weight.

Conclusion:

Assembled roving is a versatile and high-performance material that offers a unique combination of properties, making it an ideal solution for various industrial applications. Its customizable nature, cost-effectiveness, and ease of processing make it an attractive option for manufacturers seeking to improve product performance and reduce weight.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com