What is CFRT?

Carbon Fiber Reinforced Thermoplastic (CFRT) is a manufacturing process that combines the benefits of thermoplastic materials with the high strength and stiffness of carbon fibers. The process involves compounding a thermoplastic matrix with carbon fibers to create a composite material with improved mechanical properties.

How does CFRT work?

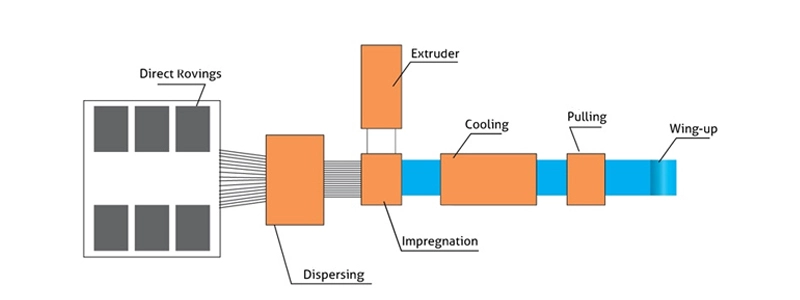

The CFRT process involves the following steps:

- Compounding: A thermoplastic matrix, such as polypropylene or polyamide, is compounded with carbon fibers.

- Sheet formation: The compounded material is then formed into a sheet using a variety of techniques, such as extrusion or calendaring.

- Thermoforming: The CFRT sheet is then thermoformed into the desired shape using heat and pressure.

- Cooling: The formed part is then cooled and ejected from the mold.

Advantages of CFRT

- High strength-to-weight ratio: CFRT materials exhibit a high strength-to-weight ratio, making them ideal for applications where weight reduction is critical.

- Improved mechanical properties: CFRT materials exhibit improved mechanical properties, such as stiffness, toughness, and fatigue resistance, compared to traditional thermoplastic materials.

- Corrosion resistance: CFRT materials are resistant to corrosion and can withstand harsh environments.

- Recyclability: CFRT materials are recyclable, making them a sustainable option.

Applications of CFRT

- Aerospace industry: CFRT materials are used in the aerospace industry for applications such as aircraft components and satellite components.

- Automotive industry: CFRT materials are used in the automotive industry for applications such as engine components, gearbox components, and chassis components.

- Industrial equipment: CFRT materials are used in industrial equipment, such as pumps, valves, and gearboxes.

- Sports equipment: CFRT materials are used in sports equipment, such as bicycle frames, golf clubs, and tennis rackets.