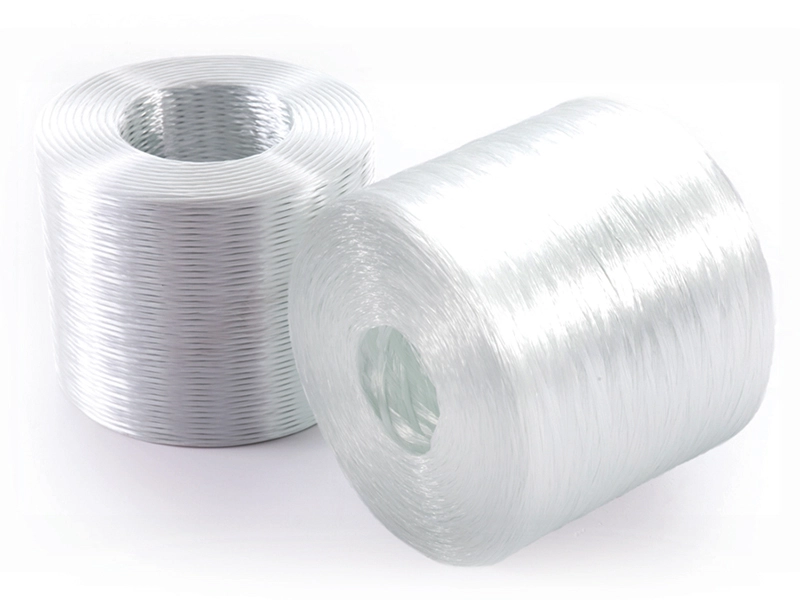

Continuous Filament Mat

Continuous Filament Mat (CFM) is a type of fiberglass reinforcement used in composite materials. It’s a popular choice for various applications due to its unique properties and advantages.

What is Continuous Filament Mat?

Continuous Filament Mat is a type of fiberglass reinforcement made from continuous glass fibers that are woven or knitted into a mat-like structure. The fibers are not chopped or cut, but rather continuous strands that are intertwined to create a strong and stable fabric.

Properties and characteristics:

CFM has several advantages that make it a popular choice for various applications:

- High strength-to-weight ratio: CFM has an excellent strength-to-weight ratio, making it an ideal choice for applications where weight reduction is critical.

- Improved laminate properties: The continuous fibers in CFM provide improved laminate properties, such as tensile strength, flexural strength, and impact resistance.

- Reduced fiber breakage: The continuous fibers in CFM reduce the likelihood of fiber breakage during processing, resulting in fewer defects and improved product quality.

- Improved dimensional stability: CFM provides improved dimensional stability, reducing the risk of warpage or shrinkage during processing.

- Easy to process: CFM is easy to process and can be molded into complex shapes using various manufacturing techniques.

Applications:

CFM is widely used in various industries, including:

- Aerospace: CFM is used in aircraft components, such as wings, fuselages, and control surfaces.

- Automotive: It is used in car bodies, chassis, and other structural components.

- Marine: CFM is used in boat hulls, decks, and other marine applications.

- Sports equipment: It is used in high-performance sports equipment, such as bicycle frames, golf clubs, and tennis rackets.

- Industrial equipment: CFM is used in industrial equipment, such as pumps, valves, and pipes.

Manufacturing process:

The manufacturing process of CFM involves several steps:

- Glass fiber production: Glass fibers are produced through a process called drawing, where molten glass is drawn through a spinneret to create fibers.

- Winding or knitting: The glass fibers are then wound or knitted into a mat-like structure using a specialized machine.

- Binding: The fibers are held together with a binder, such as a polyester or epoxy resin.

- Forming: The CFM is then formed into the desired shape using a mold or die.

- Curing: The CFM is cured in an oven or under pressure to create a solid, rigid part.

Comparison to other fiberglass reinforcements:

CFM is often compared to other fiberglass reinforcements, such as chopped strand mat (CSM) and woven roving. While CSM is easier to process and less expensive, CFM offers improved laminate properties and reduced fiber breakage. Woven roving, on the other hand, is more expensive than CFM but offers even higher laminate properties.

Overall, Continuous Filament Mat is a versatile and high-performance fiberglass reinforcement that offers improved properties and advantages over other types of fiberglass reinforcements.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com