Chongqing Polycomp International Corp

Company Profile

Chongqing Polycomp International Corporation (hereinafter referred to as “CPIC” or “the Company”), established in 1991, is an important pillar of Yuntianhua Group Co., Ltd. in the new glass fiber material industry.

As a high-tech enterprise with the core business of R&D, production and sales of glass fibers and composite materials, CPIC focuses on new high-performance materials and is committed to developing high-performance products with stable quality and continuous innovation, so as to provide customers with valuable services and application solutions.CPIC has 3 sales subsidiaries in North America, Europe, and Hong Kong of China, respectively. It has established production bases in Chongqing, Zhuhai, and Changzhou of China, as well as in Brazil, Bahrain, the United States, and Morocco. CPIC has an annual production capacity of 1 million tons of glass fiber yarns and up to 200 million meters of glass fiber cloth.CPIC produces a wide range of glass fiber products, including alkali-free glass fiber woven roving, spun yarn, chopped fiber, checked cloth, and fabric. It has earned widespread recognition from its partners for the quality of its products.

- CPIC Fiberglass Direct Roving

- CPIC Assembled Roving

- CPIC Chopped Strand Roving

- CPIC Fiberglass Yarn

- CPIC Fiberglass Texturized Roving

- CPIC Woven Fabric

- CPIC Fiberglass Felt

- CPIC Multiaxial Fabric

CPIC Fiberglass Direct Roving

Alkali-free glass fiber direct untwisted roving (hereinafter referred to as direct roving) is drawn directly from the funnel plate. Depending on the resin used, it is categorized into thermosetting direct yarn and thermoplastic direct yarn. Thermosetting direct yarns are suitable for resins like unsaturated polyester, vinyl, epoxy, and polyurethane. They are used in processes such as fiber winding, pultrusion, hand lay-up, and compression molding. End products include pipes, pressure vessels, profiles, and chemical storage tanks. Thermoplastic direct yarns are designed for resins like PP, PA, and others, and are used in processes like LFT, sheet molding, twin-screw extrusion, and GMT.

Thermoplastic Direct Roving

Alkali-free glass fiber direct untwisted roving (hereinafter referred to as direct roving) is drawn directly from the funnel plate. Depending on the resin matched with the infiltrant, it is classified into thermosetting direct yarn and thermoplastic direct yarn.

Thermosetting Direct Roving

CPIC manufactures direct, untwisted rovings, which are continuous single-strand untwisted rovings used in pultrusion molding, fabrics, and checkered fabrics. They are compatible with unsaturated polyester resins (UP), vinyl ester resins (VE), phenolic resins (Phenolic), and epoxy resins (EP). The products can be made with E-glass, ECT-glass, ECR-glass (excellent chemical resistance), and TM-glass (a clear advantage for large-scale FRP products requiring high modulus).

CPIC Assembled Roving

Alkali-free glass fiber braided roving (referred to as braided roving) is composed of multiple glass fibers braided together and is categorized into rigid braided roving and soft braided roving. Rigid braided roving has some stiffness and is primarily utilized in spraying and SMC processes. The soft braided roving is commonly used in winding, pultrusion, prepreg processes, etc. The final products include sanitary ware, yachts, car roofs, insulating rods, sports equipment, etc.

CPIC Chopped Strand Roving

Chopped glass fiber, known as chopped yarn, CPIC chopped yarn, is categorized into chopped yarn for thermoplastics, chopped yarn for BMC, and water drawn yarn. It is used in reinforced thermoplastics (e.g. PA, PET, PBT, PC, etc.) and reinforced thermosetting plastics (e.g. phenolic resins, unsaturated polyester resins, etc., commonly used in the BMC process), as well as other applications (e.g. Hydrodrawing as a substrate for wet felts). Short-cut yarns are classified as dry short-cut yarns and wet short-cut yarns based on their wet and dry states. Thermoplastic and BMC series short-cut yarns fall under dry short-cut yarns, while Hydroentanglement yarns are categorized as wet short-cut yarns.

CPIC Fiberglass Yarn

With state-of-the-art production equipment and advanced technology, CPIC is dedicated to delivering top-quality glass fiber continuous spun yarns. CPIC glass fiber yarn products are categorized into primary twisted yarn, parallel twisted yarn, bulky yarn, and direct yarn based on different processing methods and yarn forms. Primary twisted yarn consists of single twisted yarns, while parallel twisted yarn is formed by twisting two or more primary twisted yarns together. Multiple primary twisted yarns can be combined in parallel to create yarns. Bulky yarns are produced by processing primary twisted yarns, parallel twisted yarns, combining yarns, or roving yarns into textured yarns. Yarns that resemble direct yarns in appearance and do not undergo twisting are known as direct spunlace yarns. Primary twisted yarn, parallel twisted yarn, and textured yarn are the primary yarn products offered by CPIC.

CPIC Fiberglass Texturized Roving

Fiberglass texturized roving is a type of fiberglass reinforcement material that has been textured to increase its strength and durability. It is commonly used in composite materials, such as fiberglass-reinforced plastic (FRP) products, to provide additional strength and impact resistance. The textured surface of the roving allows for better adhesion between the fibers and the resin, resulting in a stronger final product. Fiberglass texturized roving is available in various sizes and configurations to suit different manufacturing applications.

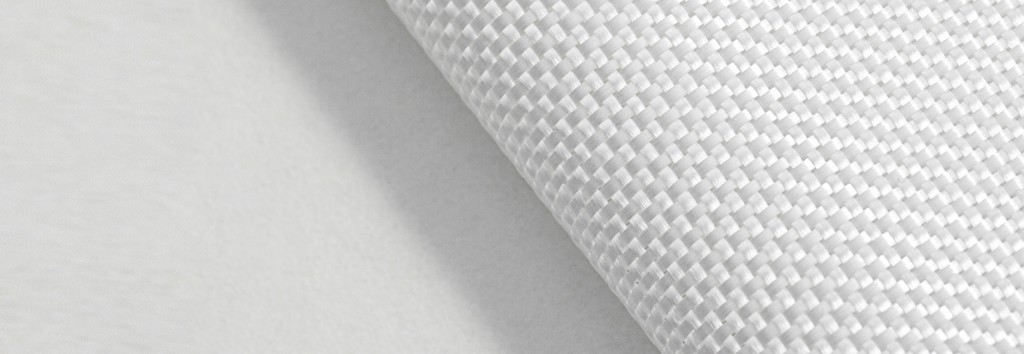

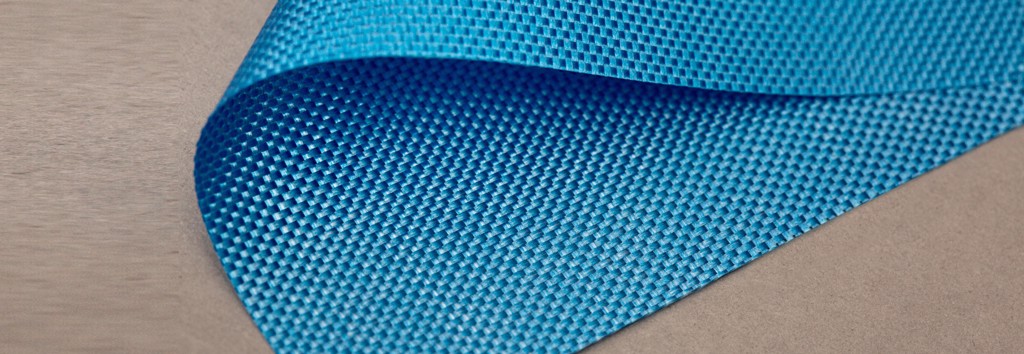

CPIC Woven Fabric

Fiberglass woven fabric is a type of fiberglass reinforcement material that is made by weaving thin strands of fiberglass together to create a strong, flexible, and lightweight fabric. It is commonly used in composite materials, such as fiberglass-reinforced plastic (FRP) products, to provide reinforcement and structural support.

Spinning Industrial Fabrics

Fiberglass woven fabric is available in a variety of weights, weaves, and finishes to suit different applications and manufacturing processes. It is often used in the aerospace, automotive, marine, construction, and other industries where high strength-to-weight ratios and durability are required.

Mesh Fabric

Mesh Fabric is a high-performance reinforcing material widely used in sports equipment, medical equipment, aircraft, and automotive parts. The grammage of the product can be adjusted according to customer needs.

CPIC Fiberglass Felt

Fiberglass Needled Felt

Fiberglass needle felt is a porous nonwoven material with a thickness ranging from 3 to 25mm. It is composed of E glass fibers with a fine diameter, carded, and needled by a felting machine. Countless small cavities form inside the fiber felt, giving the product excellent thermal insulation properties. Additionally, E glass fiber is resistant to high temperatures and offers good electrical insulation. The product is free from any adhesive, making it an environmentally friendly option with unique characteristics compared to other thermal insulation and filtration materials. Note: Needled Fiber has a fluffy structure and low thermal conductivity, making it suitable for use as thermal insulation and automotive exhaust gas filtration material. The thickness, width, and weight can be customized based on customer requirements.

CPIC Multiaxial Fabric

The yarns are arranged at specific angles (e.g. 0, 90, ±45°) in multiple layers, typically 2-6 layers. Short-cut and non-woven layers can also be included, followed by sewing the layers together with polyester yarns in a warp knitting pattern to create a multiaxial fabric, also known as multiaxial warp knitted fabric. These fabrics are rigid and effectively utilize the mechanical properties of glass fibers. Specifically, we emphasize the weight in one direction (e.g. 0 degrees) of the multiaxial fabric, referred to as unidirectional fabric. Multiaxial fabrics find applications in vacuum infusion, prepreg, winding processes, primarily in manufacturing wind turbine blades, pipes, etc. Epoxy resin (EP), polyester resin (UP), vinyl resin (VE), polyurethane resin (PU), and polyurethane resin (PU) are commonly used resins for these fabrics.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com