What is Hand Lay-up?

Hand Lay-up is a composite manufacturing process that involves laying up layers of fibers and resin by hand to create a composite part.

How does Hand Lay-up work?

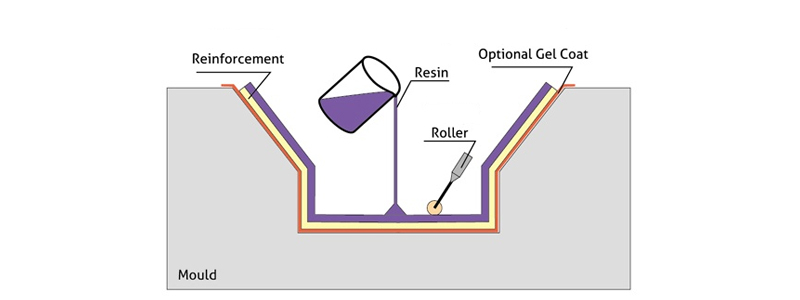

The Hand Lay-up process involves the following steps:

- Mold preparation: A mold or surface is prepared and cleaned to ensure a smooth finish.

- Fiber preparation: Fibers, such as glass or carbon fibers, are prepared and cut to the desired length.

- Resin preparation: A resin, such as epoxy or polyester, is prepared and mixed to the desired consistency.

- Laying up: Layers of fibers and resin are laid up by hand onto the mold or surface to achieve the desired thickness.

- Curing: The composite part is cured in an oven or using other curing methods to create a strong and durable bond between the fibers and resin.

Advantages of Hand Lay-up

- High quality: Hand Lay-up can produce high quality composite parts with precise control over fiber orientation and resin distribution.

- Flexibility: Hand Lay-up can be used to produce complex shapes and designs that are difficult to achieve with other manufacturing processes.

- Low capital costs: Hand Lay-up requires minimal equipment and can be done with low capital costs.

- Good surface finish: Hand Lay-up can produce composite parts with a smooth surface finish.

Applications of Hand Lay-up

- Aerospace industry: Hand Lay-up is used in the aerospace industry for lightweight components, such as aircraft structures and interior panels.

- Marine industry: Hand Lay-up is used in the marine industry for boat hulls, decks, and other components.

- Automotive industry: Hand Lay-up is used in the automotive industry for parts such as body panels, dashboards, and trim components.

- Consumer goods: Hand Lay-up is used in consumer goods, such as sporting goods, furniture, and appliances.