Ready to experience high-quality products at a price that works for you? Contact us for a quote today!

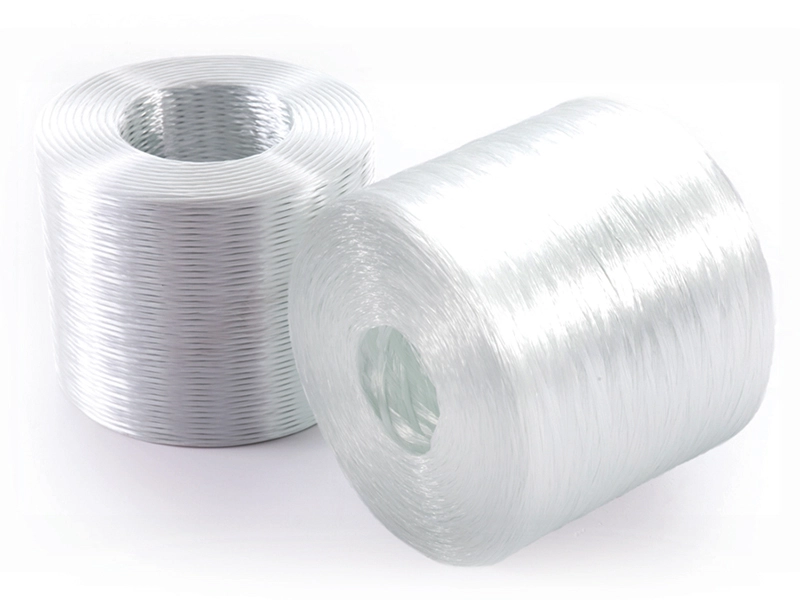

910A Roving for thermoplastic is coated with a silane-based sizing, compatible with multiple resin systems such as PA, PP and AS. It renders excellent hydrolysis resistance and thermal oxygen aging resistance to the reinforced PA parts and also performs well in reinforcing PP and AS products.

910A is designed for extrusion and injection molding processes, and is widely used in automotive, railway track fastening plates, and electrical & electronic applications.

Product Features

- Excellent mechanicalproperties

- Hydrolysis and thermal oxygen aging resistant

- Shiny surface ofthe composite product without fiberrevealed

- Smooth process and low fuzz forgood working atmosphere

Specification

| Glass type | E | |

| Sizing type | Silane | |

| Typical filament diameter (μm) | 13 | |

| Typical linear density (tex) | 2000 | |

| Example | EDR13-2000-910A | |

Technical Parameters

| Item | Linear density variation | Moisture content | Sizing content |

| Unit | % | % | % |

| Test menthod | ISO1889 | ISO3344 | ISO1887 |

| Standard range | ±5 | ≤0.20 | 0.25±0.10 |

Instructions

- The product is best used within 12 months after production, and should be kept in the original package before use.

- Care should be taken when using the product to prevent it from being scratched or damaged.

- The temperature and humidity of the product should be balanced with the ambient temperature and humidity before use, and theambient temperature and humidity should be properly controlled during the use.

Packaging

For detailed package size information, please download the product manual to view!

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area.The best temperature and humidity should be maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.