Pultrusion resins are the key component in the pultrusion manufacturing process, which is used to create continuous profiles of fiber-reinforced polymer (FRP) materials. The choice of pultrusion resin is crucial as it directly affects the final properties and performance of the pultruded product. Here are the key aspects of pultrusion resins:

- Resin Types:

- Thermoset resins are the most commonly used, including polyester, vinyl ester, and epoxy resins.

- Thermoplastic resins, such as polyamides and polypropylene, are also used in some specialized pultrusion applications.

- Resin Properties:

- Viscosity: The resin must have a low enough viscosity to effectively wet and impregnate the reinforcing fibers during the pultrusion process.

- Curing Behavior: The resin should have a suitable curing profile to ensure complete cure within the heated die.

- Mechanical Properties: The cured resin should provide the desired mechanical properties, such as strength, stiffness, and impact resistance, to the final pultruded product.

- Environmental Resistance: The resin should offer resistance to environmental factors, such as UV exposure, moisture, and chemicals, depending on the intended application.

- Fiber-Resin Compatibility:

- The resin must be compatible with the reinforcing fibers used in the pultrusion process, such as glass, carbon, or aramid fibers.

- Good fiber-resin compatibility ensures effective load transfer and optimal mechanical performance of the pultruded composite.

- Additives and Modifiers:

- Pultrusion resins may be formulated with various additives and modifiers to enhance specific properties, such as:

- Thixotropic agents to improve fiber wet-out and reduce resin drainage

- Flame retardants for fire-resistant applications

- UV stabilizers for outdoor exposure

- Toughening agents to improve impact resistance

- Pultrusion resins may be formulated with various additives and modifiers to enhance specific properties, such as:

- Resin Curing and Processing:

- Pultrusion resins are typically cured using a combination of heat and chemical initiators, such as peroxides or amine-based catalysts.

- The curing process must be carefully controlled to ensure complete and uniform cure throughout the pultruded profile.

The selection of the appropriate pultrusion resin is crucial for the success of the manufacturing process and the performance of the final pultruded product. Factors such as the desired mechanical properties, environmental conditions, and production requirements should be carefully considered when choosing the right resin system.

| Model | Type | 25℃ pa.s Viscosity | Min Gel Time | Non-volatile | MPa Tensile Strength | Elongation | MPa Flexural Strength | HDT ℃ | Application&Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 209 | PA | 0.45-0.75 | 3.0 -6.0 | 61-67 | 65 | 2 | 105 | 90 | Light color, fast speed pultrusion, suitable for common light color product. |

| 210 | PA | 0.35-0.45 | 8.0-14.0 | 61-67 | 70 | 3.5 | 112 | 70 | High strength, good rigidity, good brightness, fast speed pultrusion,suitable for high performance pultrusion product. |

| 211 | PA | 0.25-0.55 | 6.0-18.0 | 66-72 | 60 | 2.5 | 100 | 85 | Good surface gloss,High strength,high toughness,Good heat resistance,used for doors,Windows,tent poles. |

| 2109 | IPA | 0.46-0.84 | 4.5 -8.4 | 58-64 | 70 | 3 | 110 | 80 | Good surface gloss,Excellent weather resistance,High strength,high toughness,Excellent eletric properties and wave-transitivity,Excellent resistance to dimensional deformation. |

Pultrusion resins have a wide range of applications in various industries due to the versatility and advantages of pultruded composite materials. Here are some of the common applications of pultrusion resins:

- Construction and Infrastructure:

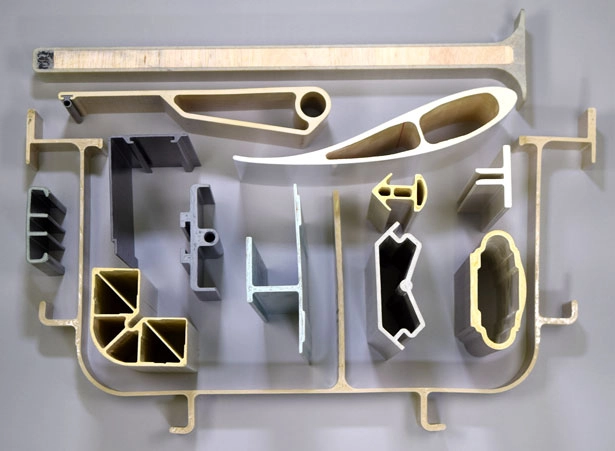

- Structural members: Pultruded beams, columns, and profiles for building construction, bridges, and other infrastructure projects.

- Reinforcement: Pultruded rods and rebars for concrete reinforcement, offering corrosion resistance and high strength-to-weight ratio.

- Architectural elements: Pultruded profiles for window frames, door frames, and other building components.

- Electrical and Telecommunication:

- Electrical conduits and cable trays: Pultruded FRP products offer lightweight, non-conductive, and corrosion-resistant properties for electrical applications.

- Utility poles and crossarms: Pultruded FRP utility poles and crossarms for power transmission and distribution lines.

- Telecommunication equipment: Pultruded components for telecommunication infrastructure, such as antenna mounts and equipment enclosures.

- Transportation:

- Automotive and aerospace: Pultruded components for vehicle interiors, exteriors, and structural applications, providing weight savings and design flexibility.

- Rail and marine: Pultruded profiles for rail cars, ships, and other transportation equipment, offering corrosion resistance and low maintenance.

- Industrial and Corrosive Environments:

- Chemical processing equipment: Pultruded FRP pipes, tanks, and other components for handling corrosive chemicals and fluids.

- Pulp and paper industry: Pultruded components for pulp and paper mills, where corrosion resistance and low maintenance are essential.

- Oil and gas industry: Pultruded products for offshore platforms, pipelines, and other oil and gas infrastructure.

- Renewable Energy:

- Wind turbine blades: Pultruded FRP spar caps and other structural components for wind turbine blades, leveraging their high strength-to-weight ratio.

- Solar panel frames: Pultruded FRP frames for photovoltaic solar panels, offering corrosion resistance and lightweight design.

The choice of pultrusion resin depends on the specific requirements of the application, such as mechanical properties, environmental conditions, and production processes. Manufacturers work closely with resin suppliers to develop customized resin formulations that meet the unique needs of their pultruded products and target markets.