Vacuum/RTM Resin refers to the type of thermosetting resin used in the vacuum-assisted resin transfer molding (VARTM) and resin transfer molding (RTM) composite manufacturing processes.

The key characteristics of Vacuum/RTM Resins include:

- Low to Medium Viscosity:

- Typical viscosity range is 100-500 centipoises (cP).

- This low viscosity allows the resin to easily flow and impregnate the reinforcement fibers.

- Compatibility with Reinforcements:

- The resin must be compatible with the reinforcement materials, such as glass, carbon, or aramid fibers.

- Good wetting and adhesion between the resin and fibers is important for mechanical performance.

- Controlled Curing Behavior:

- The resin system includes catalysts, accelerators, and other additives to control the curing rate and extent of crosslinking.

- Proper curing ensures the desired mechanical, thermal, and chemical properties of the composite.

- Suitability for VARTM and RTM Processes:

- The resin viscosity and flow characteristics are tailored for effective impregnation under vacuum or injection pressure.

- Resins may be formulated to have a suitable pot life and cure time for the specific manufacturing process.

Common Vacuum/RTM Resin types include:

- Epoxy resins

- Polyester resins

- Vinyl ester resins

The selection of the appropriate Vacuum/RTM Resin depends on the specific requirements of the composite application, such as mechanical performance, environmental resistance, and manufacturing process parameters.

Here are the key points about the use of resin in vacuum-assisted resin transfer molding (VARTM) and resin transfer molding (RTM) processes:

Resin Selection:

- Common thermosetting resins used include epoxy, polyester, and vinyl ester.

- Resin selection is based on desired mechanical properties, chemical resistance, curing characteristics, and compatibility with reinforcements.

- Low to medium viscosity resins (100-500 cP) are preferred for good impregnation.

Resin Preparation:

- Resins may require mixing with catalysts, accelerators, or other additives to control curing.

- Proper mixing and degassing is important to remove trapped air or volatiles.

Resin Injection and Impregnation:

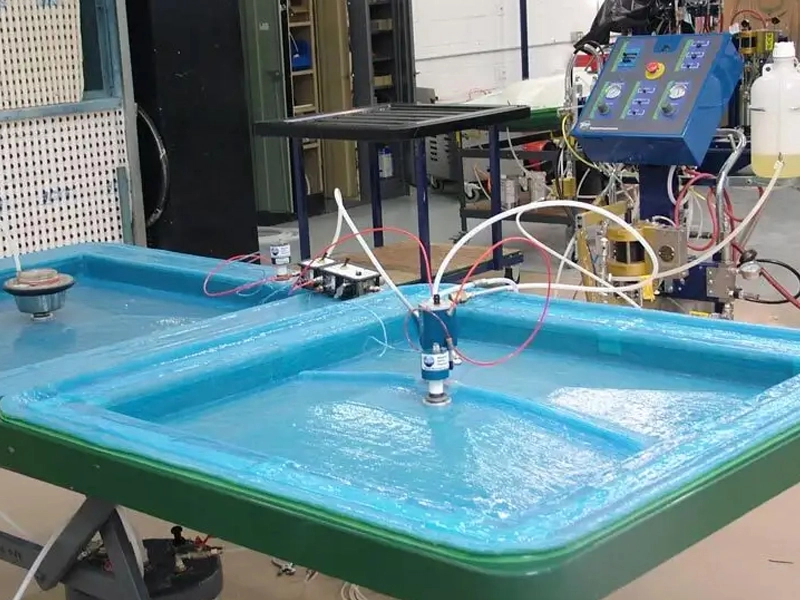

- In VARTM, resin is drawn into the mold by vacuum, while in RTM it is actively injected under pressure.

- Resin flow and reinforcement impregnation are influenced by mold design, preform permeability, and injection parameters.

- The goal is to achieve complete and uniform resin impregnation without excessive resin flow or wastage.

Resin Curing:

- Curing parameters like temperature, time, and use of catalysts/accelerators are controlled.

- Proper curing ensures the desired degree of crosslinking and dimensional stability.

Defect Mitigation:

- Common defects include voids, dry spots, resin-rich/starved areas, and poor fiber-resin bonding.

- These can be minimized by optimizing resin viscosity, injection, and curing.

Resin Waste and Disposal:

- Unused resin, solvents, and other waste must be disposed of properly.

- Recycling and waste management practices help minimize environmental impact.

Safety Considerations:

- Appropriate PPE and ventilation are required when handling resins.

- Spill containment measures are important for worker and environmental safety.

Careful resin selection, preparation, and process control are crucial for producing high-quality composite parts using VARTM and RTM techniques.

| Model | Type | 25℃ pa.s Viscosity | Min Gel Time | Non -volatile | MPa Tensile Strength | Elongation | MPa Flexural Strength | HDT ℃ | Application&Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 9501P | PA | 0.12-0.17 | 30-60 | 49-55 | 70 | 2.5 | 120 | 80 | Lower peak temperature, small shrinkage, high strength, fast curing, good water and heat resisting, suitable for medium or large size FRP product. |

| 9502P | PA | 0.12-0.17 | 20-25 | 49-55 | 70 | 2.5 | 120 | 80 | Lower peak temperature, small shrinkage, high strength, fast curing, good water and heat resisting, suitable for medium or small size FRP product. |

| 241 | VE | 0.14-0.20 | 30-120 | 63-67 | 80 | 5.0 | 130 | 110 | Applications include high performance structural components with large dimensions and high fibre content, such as large wind turbine blades, as well as applications for FRP products with high requirements for strength and toughness, and complex structural products. |

Here are some frequently asked questions (FAQs) about the use of resin in vacuum-assisted resin transfer molding (VARTM) and resin transfer molding (RTM) processes:

- What types of resins are commonly used in VARTM and RTM?

- The most common resins used in VARTM and RTM are thermosetting resins, such as epoxy, polyester, and vinyl ester. These resins provide good mechanical properties, chemical resistance, and compatibility with a variety of reinforcement materials.

- How does the resin viscosity affect the VARTM and RTM processes?

- The resin viscosity should be low enough to allow for proper impregnation of the reinforcement, but not too low, as it can lead to excessive resin flow and wastage. The optimal viscosity range is typically between 100 and 500 centipoises (cP).

- What factors influence the resin-to-fiber ratio in VARTM and RTM?

- The resin-to-fiber ratio is influenced by factors such as the reinforcement type, preform permeability, resin injection pressure, and the mold design. The target ratio is typically between 30-50% resin by volume.

- How is the resin curing process controlled in VARTM and RTM?

- The curing process is controlled by adjusting parameters such as temperature, time, and the use of catalysts or accelerators. Proper curing ensures the desired mechanical properties and dimensional stability of the final part.

- What are the common defects associated with resin application in VARTM and RTM?

- Potential defects include voids, dry spots, resin-rich or resin-starved areas, and poor fiber-to-resin bonding. These can be caused by improper resin mixing, injection, or curing.

- How is the resin waste and disposal handled in VARTM and RTM?

- Unused resin, contaminated solvents, and other waste materials should be disposed of according to local environmental regulations. Proper containment and recycling of waste materials can help minimize the environmental impact.

- What are the safety considerations when handling resins in VARTM and RTM?

- Proper personal protective equipment (PPE), such as gloves, goggles, and respirators, should be used when handling resins. Adequate ventilation and spill containment measures are also important for worker safety and environmental protection.

Understanding the proper selection, application, and control of resins is crucial for ensuring the quality and performance of parts produced using VARTM and RTM processes. Addressing these resin-related FAQs can help operators and engineers optimize these manufacturing techniques.

Vacuum/RTM resins are widely used in the fabrication of high-performance composite parts across various industries, including:

- Aerospace:

- Structural components for aircraft, spacecraft, and satellites

- Radomes, fairings, and other aerodynamic structures

- Composite reinforced fuselage and wing structures

- Automotive:

- Body panels, hoods, and trunk lids

- Structural components like chassis, suspension, and drivetrain parts

- Composite leaf springs and other suspension components

- Wind Energy:

- Wind turbine blades

- Nacelle and other structural components

- Marine:

- Boat hulls, decks, and superstructures

- Propeller shafts and other marine components

- Infrastructure:

- Bridges, beams, and other structural elements

- Reinforced concrete and masonry repair

- Sports and Recreation:

- Sporting goods like skis, snowboards, and bicycle frames

- Recreational vehicles like kayaks and canoes

The key advantages of using Vacuum/RTM resins in these applications include:

- High strength-to-weight ratio compared to metals

- Corrosion resistance and environmental durability

- Design flexibility for complex shapes and structures

- Improved manufacturing efficiency and reduced waste

- Potential for lower part costs through automation

Careful selection and processing of the Vacuum/RTM resin is crucial to achieve the desired mechanical, thermal, and chemical performance in the final composite part. Factors like resin chemistry, viscosity, and curing behavior must be optimized for the specific manufacturing process and application requirements.