What is SMC?

SMC stands for Sheet Molding Compound, which is a type of composite material that combines fibers, such as glass or carbon fibers, with a thermoset matrix.

How does SMC work?

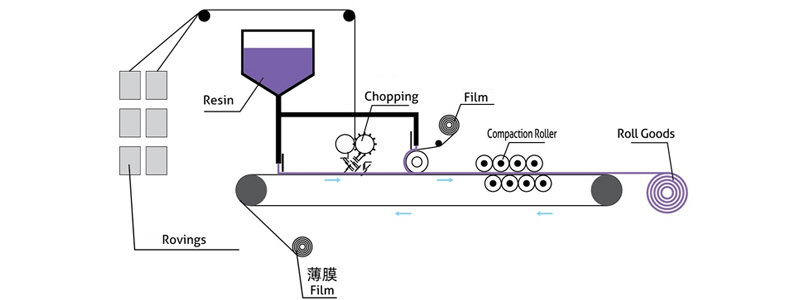

The SMC process involves the following steps:

- Fiber preparation: Fibers, such as glass or carbon fibers, are prepared and cut to the desired length.

- Compounding: The fibers are mixed with a thermoset matrix, such as polyester or epoxy, to create a composite material.

- Sheet formation: The composite material is formed into a sheet shape using a combination of heat and pressure.

- Cutting and shaping: The sheet is cut and shaped to the desired form using various machining techniques.

- Assembly: The SMC parts are assembled into the final product using various fastening methods.

Advantages of SMC

- High strength-to-weight ratio: SMC materials offer a high strength-to-weight ratio, making them ideal for lightweight applications.

- Improved impact resistance: The fibers in SMC materials provide improved impact resistance compared to traditional thermoplastics.

- Good dimensional stability: SMC materials exhibit good dimensional stability, making them suitable for applications where precision is critical.

Applications of SMC

- Automotive industry: SMC materials are used in the automotive industry for parts such as body panels, hood components, and trunk lids.

- Aerospace industry: SMC materials are used in the aerospace industry for lightweight components, such as aircraft structures and interior panels.

- Industrial equipment: SMC materials are used in industrial equipment, such as machinery components and structural frames.