What is Spray-up?

Spray-up is a manufacturing process that involves spraying a mixture of resin and fibers onto a mold or substrate to create a strong and lightweight part. The process is often used to create large, complex parts with high strength-to-weight ratios.

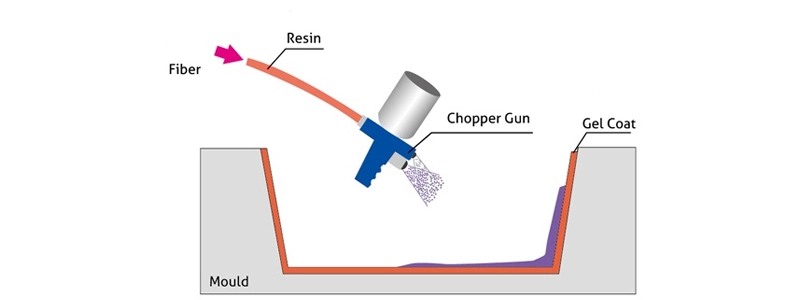

How does Spray-up work?

The Spray-up process involves the following steps:

- Material preparation: A mixture of resin and fibers is prepared and fed into a spray gun.

- Spraying: The mixture is sprayed onto a mold or substrate using high pressure.

- Layering: The mixture is layered onto the mold or substrate to achieve the desired thickness and shape.

- Curing: The part is then cured in an oven or using a catalyst to create a strong and durable bond between the fibers and resin.

Advantages of Spray-up

- High strength-to-weight ratio: Spray-up parts exhibit a high strength-to-weight ratio, making them ideal for applications where weight reduction is critical.

- Improved impact resistance: Spray-up parts have improved impact resistance compared to traditional materials.

- Corrosion resistance: Spray-up parts are resistant to corrosion and can withstand harsh environments.

- Increased design flexibility: Spray-up allows for complex geometries and designs that would be difficult or impossible to achieve with traditional manufacturing processes.

Applications of Spray-up

- Marine industry: Spray-up parts are used in the marine industry for applications such as boat hulls, decks, and superstructures.

- Aerospace industry: Spray-up parts are used in the aerospace industry for lightweight components, such as aircraft structures and interior panels.

- Industrial equipment: Spray-up parts are used in industrial equipment, such as tanks, pipes, and valves.