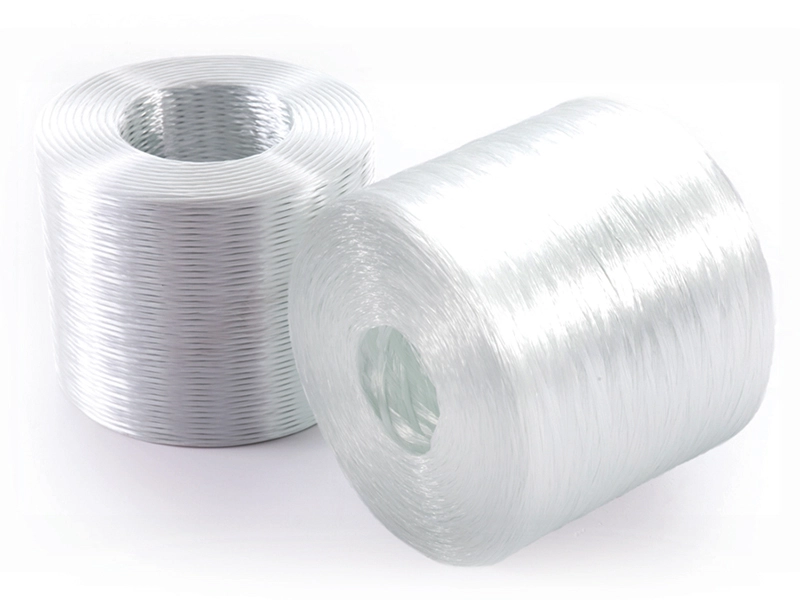

Chopped Strand Mat

What is Chopped Strand Mat?

Chopped Strand Mat (CSM) is a type of fiberglass reinforcement used in composite materials. It is a non-woven mat made from chopped glass fibers, typically 1-4 inches (2.5-10 cm) in length, that are bonded together with a resin or binder.

Properties and characteristics:

CSM has several key properties and characteristics that make it a popular choice for composite manufacturing:

- Easy to use: CSM is easy to handle and can be easily molded into complex shapes.

- Good mechanical properties: CSM has good mechanical properties, including tensile strength, flexural strength, and impact resistance.

- Chemical resistance: CSM is resistant to many chemicals, including water, acids, and bases.

- Thermal insulation: CSM has good thermal insulation properties, making it suitable for applications where heat resistance is required.

- Cost-effective: CSM is a cost-effective material compared to other types of fiberglass reinforcements.

Applications:

CSM is widely used in various industries, including:

- Automotive: CSM is used in car bodies, bumpers, and other components.

- Marine: CSM is used in boat hulls, decks, and other marine applications.

- Aerospace: CSM is used in aircraft components, such as wings, fuselages, and control surfaces.

- Construction: CSM is used in building insulation, roofing, and wall panels.

- Sports equipment: CSM is used in surfboards, kayaks, and other sports equipment.

Manufacturing process:

The manufacturing process of CSM involves several steps:

- Glass fiber production: Glass fibers are produced through a process called drawing, where molten glass is drawn through a spinneret to create fibers.

- Chopping: The glass fibers are then chopped into short strands, typically 1-4 inches (2.5-10 cm) in length.

- Bonding: The chopped strands are then bonded together with a resin or binder to create a mat-like structure.

- Forming: The CSM is then formed into the desired shape using a mold or die.

- Curing: The CSM is cured in an oven or under pressure to create a solid, rigid part.

Comparison to other fiberglass reinforcements:

CSM is often compared to other fiberglass reinforcements, such as continuous filament mat (CFM) and woven roving. While CFM offers improved laminate properties, CSM is easier to process and less expensive. Woven roving, on the other hand, is more expensive than CSM but offers even higher laminate properties.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com