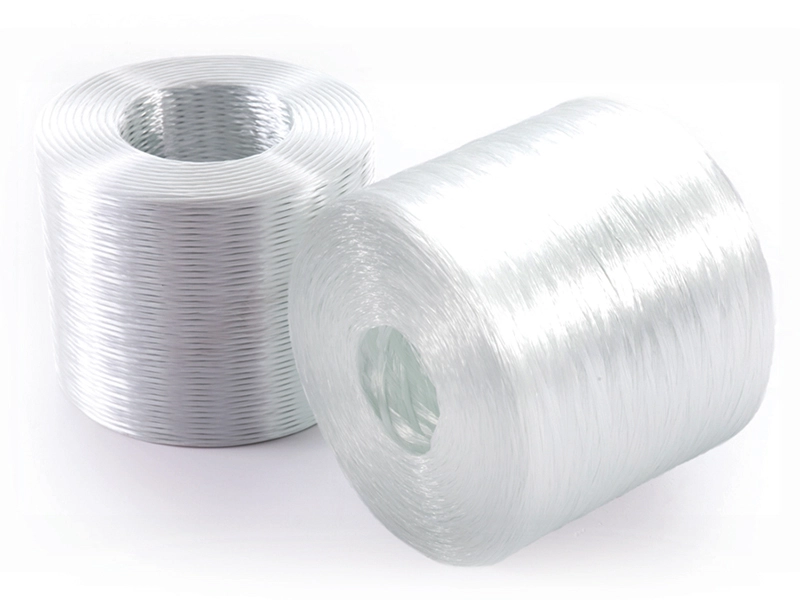

Direct Roving

What is Direct Roving Fiberglass?

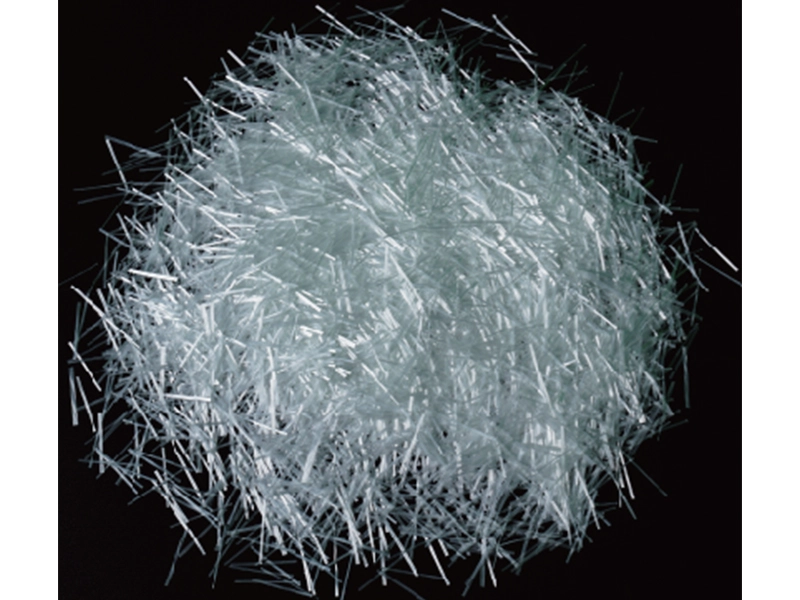

Direct roving fiberglass is a type of fiberglass product that is used to manufacture composite materials. It is a bundle of continuous glass fibers that are wound together to form a rope-like strand. The fibers are not chopped or cut, but rather remain continuous throughout the length of the roving.

Characteristics

Direct roving fiberglass has several key characteristics that make it useful for composite manufacturing:

- High strength-to-weight ratio: Direct roving fiberglass has a high strength-to-weight ratio, making it an ideal material for applications where weight reduction is critical.

- Good fatigue resistance: The continuous fibers in direct roving fiberglass provide excellent fatigue resistance, making it suitable for applications where the material will be subjected to repeated loading and unloading.

- Low moisture absorption: Direct roving fiberglass has a low moisture absorption rate, which makes it resistant to water and humidity.

- Good chemical resistance: Direct roving fiberglass is resistant to many chemicals, including acids and alkalis.

Applications

Direct roving fiberglass is used in a variety of applications, including:

- Composite manufacturing: Direct roving fiberglass is used to manufacture composite materials, such as boat hulls, aircraft components, and automotive parts.

- Pultrusion: Direct roving fiberglass is used in the pultrusion process to manufacture composite profiles, such as rods, tubes, and beams.

- Filament winding: Direct roving fiberglass is used in the filament winding process to manufacture composite cylinders, tanks, and other pressure vessels.

- Hand layup: Direct roving fiberglass is used in the hand layup process to manufacture composite parts, such as boat hulls and aircraft components.

Benefits

The benefits of using direct roving fiberglass include:

- Improved mechanical properties: Direct roving fiberglass provides improved mechanical properties, such as strength, stiffness, and fatigue resistance.

- Reduced weight: Direct roving fiberglass is lighter than traditional materials, making it ideal for applications where weight reduction is critical.

- Corrosion resistance: Direct roving fiberglass is resistant to corrosion, making it suitable for applications where exposure to water or chemicals is a concern.

- Cost-effective: Direct roving fiberglass is a cost-effective material compared to other composite materials.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com