JUSHI Fiberglass For Thermoplastics

Extrusion and Injection Processes

End-Use Markets

The reinforcements (glass fiber roving or chopped strands) and thermoplastic resin are mixed in an extruder. After cooling, they are chopped into reinforced thermoplastic pellets. The pellets are fed into an injection molding machine to form finished parts.

Roving for Thermoplastics

Coated with silane-based agents, our glass rovings for thermoplastics are ideal options for reinforcing many resin systems such as PA, PBT, PET, PP, ABS, AS and PC. The rovings have excellent processability and dispersion, imparting outstanding physical and mechanical properties to the composite products.

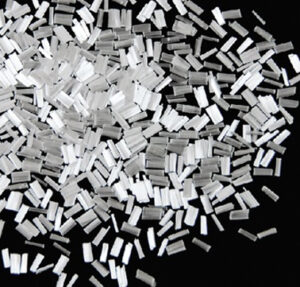

Chopped Strand for Thermoplastics

Glass fiber chopped strand for thermoplastics uses a specifically designed sizing with silane-based coupling agent. It has good compatibility with PA, PBT, PET, PP, AS, ABS, PC, PPS, m-PPO, LCP and other matrix resins. The product has excellent strand integrity and fluidity, as well as good molding and processability, offering superior mechanical properties and surface quality to the composite parts.

LFT Process

LFT-D

Polymer pellets and glass roving are all introduced into a twin-screw extruder where the polymer is melted and compound is formed. Then the molten compound is directly molded into the final parts by injection or compression molding process.

LFT-G

The thermoplastic polymer is heated to a molten phase and pumped into the die-head. The continuous roving is pulled through a dispersion die to ensure the glass fiber and polymer impregrated fully and to get consolidated rods. After cooling, the rod is chopped into reinforced pellets.

Direct Rovings for LFT

Direct Rovings for LFT are coated with a silane-based sizing and compatible with PP, PA, TPU and PET resins.

GMT Process

Generally two layers of reinforcing mat are sandwiched between three layers of polypropylene, which is then heated and consolidated into a semi-finished sheet product. The semi-finished sheets are then heated and molded by stamping or compression process to make complex finished parts.

Alkali free fiberglass roving for GMT

GMT non alkali glass fiber roving is made of special sizing agent, which has good compatibility with modified PP resin, moderate fiber stiffness, excellent band forming and dispersion, and can give the composite excellent mechanical and electrical properties.

| Product Code | Product Features |

|---|---|

| 360A | Direct roving for GMT-UD, excellent weaving property |

| 360H | Direct roving for GMT, good dispersion |

| 522 | Assembled roving for GMT-RD, excellent choppability |

CFRT Process

A molten mixture of polymer resin and additives is obtained through an extruder. The continuous filament roving is dispersed and impregnated by pulling through the molten mixture. After cooling, curing and coiling, the final material is formed.

Direct Rovings for CFRT

Direct Rovings for CFRT are compatible with modified PP and PE resins and have excellent mechanical properties.

OFFERINGS

FIBERGLASS PRODUCTS

FOLLOW US

RESOURCES

TF FRP

Email: info@tffrp.com